HIP Advantages

Hot Isostatic Pressing

When being densified within a HIP system, components are processed at pressures up to 207MPa (~30,000PSI) within

the chamber. To achieve the required pressure, an inert gas is utilised to prevent chemical reactions within the processed material and the pressure is applied isotropically. Argon is the preferred process gas utilised at Wallwork HIP, ensuring customer components are processed according to the leading industry standards, which is vital when operating at temperatures up to 1250°c.

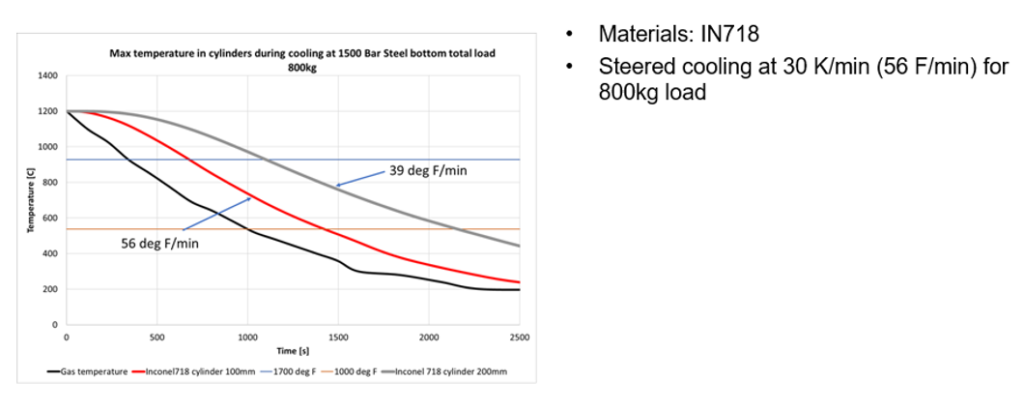

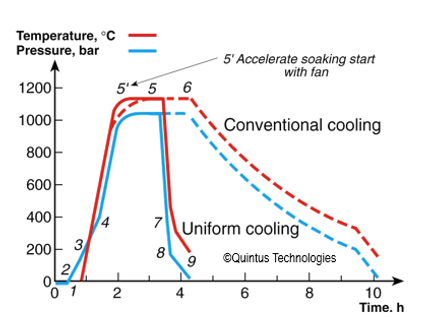

HIP systems have historically relied upon natural cooling, which can lead to significantly longer processing times and suboptimal mechanical properties. Uniform Rapid Cooling® by Quintus Technologies removes this problem, allowing the fast and efficient processing of customer parts, whilst allowing specific and optimal cooling rates to be repeatedly selected according to the needs of our customers.

Depending on the material and process requirements, components can benefit from specific cooling rates.

Depending on the material and process requirements, components can benefit from specific cooling rates.

Examples of this includes:

- Aluminium Alloys – LM25 / 2024 / 6061 / 7075

- Titanium Alloys – Ti-6246 / Ti-6AL-4V

- Low Alloyed Steels – L2 / L6

- Tool Steel – A2 / D2 / 01 / H13 / M2 / M42 / P20

Known industry variables are utilised to ensure that the components are treated accordingly and exceed customer requirements for the designed product. Whether a short 4-hour cycle is used or a longer process time, Wallwork HIP will be on hand to answer any queries. The typical processing route for HIP components is shown below. However with HIP in combination with URC® and HPHT as available at Wallwork HIP, it is possible to simplify this typical manufacturing route by optimising the HIP stage and removing the need for post-HIP heat treatment – since this can be performed within the HIP system.